Successful Fibre Network Repair and Restoration at Wind Farm

Project Overview

The Challenge and Solution

The primary challenge during the fibre network repair was to identify and fix faults on the return leg at the last turbine — a particularly critical point in the network. The environment added complexity, as turbines are located in exposed, high-altitude areas with harsh weather conditions, requiring strict adherence to health and safety protocols.

Our Solution

1. Systematic Fault Identification: Our fibre network repair process began with thorough diagnostics and testing across each fibre core to locate the faults precisely. By methodically isolating the affected cores, we pinpointed the issues at two turbines, including the last turbine on the string — the most critical point in the redundant path.

- Identified incorrect patch cords being used in multiple locations

- Location of systematic weaknesses within the fibre network. This included fibre break out boxes that allowed engineers access to the primary incoming cable.

- Identicication of active equipment specification. This enable us to calculate the exact loss limits and appropriate network overhead.

2. Fibre Splicing and Repairs:

- Faulty fibre cores were re-spliced using new pigtails.

- Replaced legacy fibre breakout boxes with new secure system connections.

- New patch cords were installed between passive and active equipment in turbine enclosures and at the SCADA control cabinet.

- Fibre end faces were carefully cleaned using lint-free wipes and isopropyl alcohol, with inspection under a fibre microscope to ensure optimal signal transmission.

3. Fibre Cleaning & Maintenance

As part of the fibre network repair, one of the most important — yet often overlooked — steps is ensuring connectors are properly cleaned. Even tiny amounts of dust, oil, or residue can cause:

- Signal loss (insertion loss): reducing transmission quality and speed.

- Reflection issues (return loss): creating instability in sensitive systems like VoIP, video conferencing, or high-speed data.

- Permanent damage: contaminants can “burn” into the connector end face when light passes through, leading to costly replacements.

In challenging environments, such as wind farms, end face contamination is often the leading cause of network degradation. Cleaning during installation and repairs ensures reliable connectivity and prevents future faults.

At Twisted Pair Technologies, we follow industry best practices to minimise these risks:

- Lint-free wipes & specialist cleaning tools: Only fibre-approved wipes, cassettes, or one-click cleaners are used—ordinary cloths or tissues leave lint.

- High-purity cleaning fluids: Approved isopropyl alcohol or specialist fibre solutions are applied sparingly to avoid residue.

- Inspection before & after cleaning: Every connector is checked with a fibre inspection scope before cleaning, then re-inspected afterwards to verify cleanliness.

- “Clean before connect” policy: All connectors are cleaned prior to mating, even factory-sealed ones.

Why It Matters?

- Network stability: Reduces the chance of intermittent or unexplained faults.

- Extended infrastructure lifespan: Prevents scratches or pitting, ensuring connectors last longer.

- Cost savings: Avoids unnecessary troubleshooting, downtime, or replacements caused by contaminated connectors.

By prioritising fibre cleanliness, Twisted Pair Technologies ensures every connection is stable, efficient, and built for long-term performance.

4. Network Verification and Proactive Testing:

Following the fibre network repair, Twisted Pair Technologies verified the integrity of the ring topology by testing additional turbine strings. This process identified fibres nearing their loss budget limits, allowing for proactive maintenance planning and ensuring the network remained fully resilient.

5. Cabling Organization and Documentation: We reorganized the cabling within the substation cabinet, labeling all connections and updating documentation. This not only improved immediate fault-finding efficiency but also enhanced long-term network reliability. Verification of the network topology confirmed that all turbines were connected according to onsite documentation.

Understanding Fibre Ring Topology

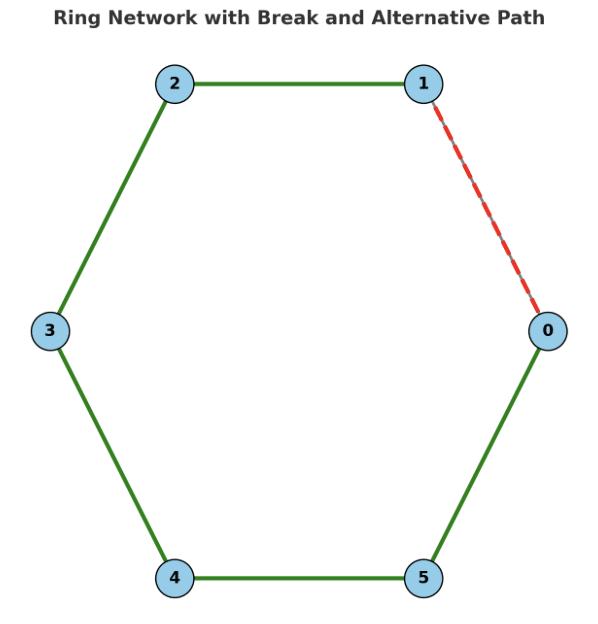

The wind farm’s network is structured as a ring topology, which is widely used in industrial fibre networks for its redundancy benefits. Each turbine connects to two fibre paths: a primary line and a redundant return leg.

Red dashed line = the broken link

Green path = the rerouted alternative traffic path

Gray links = normal operational connections

The advantage is clear: if a fibre break occurs anywhere along the network, communications can reroute in the opposite direction, maintaining connectivity for all turbines. The fault at the last turbine was particularly significant because any failure at this point could compromise the redundancy of the entire string. By understanding this topology, our engineers were able to prioritize fault location and repair, ensuring minimal disruption to the wind farm’s operations.

Results

The project was completed efficiently and delivered both immediate fixes and long-term resilience for the wind farm’s fibre network. Our work ensured:

- Restored communications along the return leg, including the critical last turbine to safeguard full redundancy across the network.

- Proactive improvements through testing additional turbine strings, which allowed us to identify fibres approaching their loss budget and address potential risks before failure occurred.

- Optimised fibre performance by carefully cleaning and inspecting end faces, significantly reducing the likelihood of optical loss and ensuring reliable signal transmission.

- Enhanced operational reliability and safety, enabling uninterrupted turbine data to flow back to central monitoring systems, supporting both efficiency and safety protocols.

- Streamlined fault-finding and future maintenance by reorganising cabinet cabling, implementing precise labelling, and updating documentation, making future diagnostics quicker and more accurate.

Together, these measures not only restored the wind farm’s communications but also strengthened the network’s long-term performance. By combining technical precision with proactive maintenance, Twisted Pair Technologies demonstrated the value of addressing both current issues and potential future challenges.

At Twisted Pair Technologies, we don’t just repair — we build resilient networks. Alongside fibre optic maintenance and repairs, we provide structured cabling, fibre installations, wireless surveys, access point solutions, network cabinet services, and business connectivity systems. Get in touch with our team to learn how we can keep your network performing at its best.

Key Accomplishments

- Restored full fibre network redundancy

- Repaired and re-spliced damaged fibre cores

- Implemented professional fibre cleaning protocols

- Verified and optimised the network topology

- Conducted proactive testing

- Improved overall network reliability and safety