Machine Vision Excellence for Mainetti

Twisted Pair, Machine Vision with Mainetti to inspect 12 million parts

Mainetti found a fault during routine quality checks on the coat hanger hooks, which meant they could not be used and jammed the machinery causing significant downtime.

As Mainetti were already using Scorpion Machine Vision software, we worked with them to develop an offline inspection system to check all 12 million parts produced.

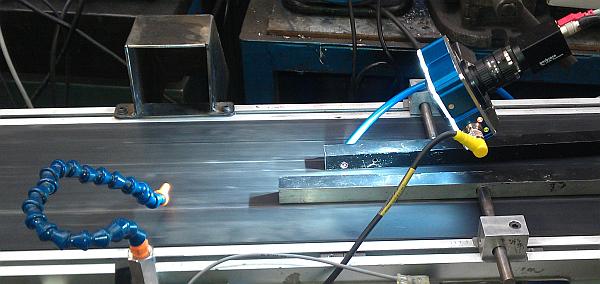

After a combination of on & off site work by both Mainetti and Twisted Pair engineers a complete system was developed, including conveyor, lenses, lighting, camera, software and air reject mechanism.